The Story of the MultiPlug Edge Computing Platform

A new version of MultiPlug 2.2.82 has been released this month and it did remind me that I have never told the story of MultiPlug’s origins, so here it is

Picture the scene

I was an undergraduate in 2006 working for a manufacturer of electronic manufacturing equipment. I had fallen into it only because the company was half way between my family home and the University I attended. It was noticeable even then that most of my peers had secured jobs in what now we would call the Digital Economy, also known as the dot com.

Meanwhile we were creating desktop applications that ran on Windows which would allow our customers to control the equipment we manufactured directly from an attached touchscreen.

Even during this time period it was becoming more common to do administrative tasks using a web browser rather than a separate desktop application. Gmail for example was launched in 2004 which solely uses it.

At that time I saw no link between what I was doing as a day job and the growth that was happening in the digital economy.

What I did know is that data was the future and we needed to invest in it. The web browser was becoming increasingly powerful and one of the big benefits of using it is you only need to install it once rather than a set of applications for all your needs. It was a reincarnation of the Server Terminal model.

The Challenge

Our industry was very customer driven. Innovation was poor and by the time customers requested features they wanted them yesterday so we were always chasing our tail.

This started to highlight itself around 2012 when data centric projects started to become the norm. Integrating with foreign systems meant we had to understand the protocols, datasets and how to serialise the data. We started to hard-code solutions on a per-customer basis but the management outside the software team soon realised this was not going to scale.

Working at the coalface of some of these projects I knew we needed to create a data centric software platform to guide the development teams and to create an API (Application Programming Interface).

This was radical to the company however because the customer would not be the end customer, it would be another software developer, whether that be an internal team or an external integrator or even a developer working for our end customer.

We didn't have a CTO (Chief Technology Officer) so we didn't have anybody at the board level to take this long-term thinking strategy move and ultimately take the risk. We would have to bundle this work into other projects using the umbrella term of the MES Strategy. The Manager tasked with this job was new to his role so I had to wait for him to find his feet and pounce when the time was right. Spoiler, this never occurred.

Realising that Innovation was poor, management came to the conclusion that the reason was, we weren't being given any time to innovate. After all, innovation is Play, so if everyone is focusing on client based work, no innovation would occur. We were given 10% of our week to work on innovation projects that could be decided by ourselves. A simple committee gave us the green light and we were encouraged to collaborate with others.

This didn't stop those colleagues who believed they should focus on 'real work' Also Known As the work to please their manager, so we had to make the first innovation projects successful to prove the naysayers wrong.

The Birth of Exposé

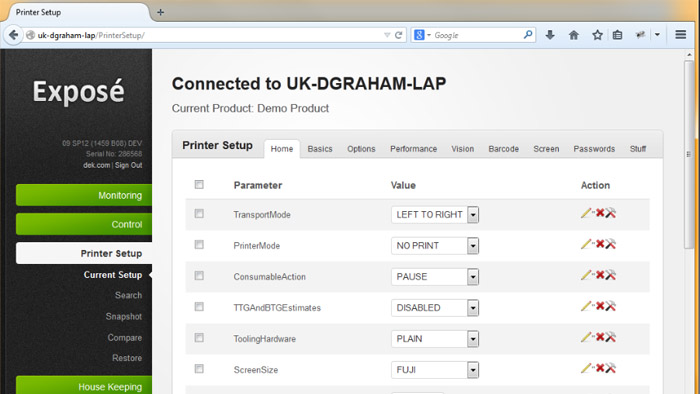

While the software data platform had to wait for the management to give the green light, I formed a plan to demonstrate what we could achieve by creating a web browser based user interface at the application layer. This would be visually stimulating for those that aren't software folk and easy to market as a concept to future customers.

Our touchscreen desktop application was already too cumbersome to use for complex configuration and because it was based on the desktop, you couldn't monitor a machine from a distance away from it. We didn't have any Apple grade User Experience engineers so there was no chance we would do a good job in fixing this.

The web browser solved both. You can easily create multiple pages where configuration and setup can occur and by its nature you could monitor a machine's activities by a network connection.

There was already talk of creating a simple user interface for basic user interactions and new machine equipment had already been given the green light to be developed so if successful the concept could be rolled out on this.

Exposé was born as my 10% time innovation project. I named it this as it exposed the data of the machine.

It provided a simple dashboard hosted on Microsoft IIS that was running on the manufacturing equipment.

It allowed you to Start and Stop the equipment, read log files, change basic parameters and conduct software upgrades of the desktop application, as if you were a customer support engineer using it remotely.

Trying to become a role model of how these projects should be delivered, I set up a number of presentations of the final result to all the disciplines of the company.

From production to sales, customer support, marketing, product management, right up to the board level of directors. They all loved it.

To this day I'm still not sure if they were so positive only because they were being polite or it was just unusual for someone to step up and present an idea to them.

The Takeover

A director suggested I buddy the project up with a customer to validate it. I sighed. While I appreciated his enthusiasm, it was still a precious idea that needed to be matured before being shown to the world. I preferred to work on it internally with either the customer support, marketing or production teams, to see if it would be beneficial to them first before pivoting it outward to the customers.

During the Spring of 2014 it was announced that the company would be taken over. I knew this would result in distractions within the company as I had already lived through the financial crisis of 2008 and saw how the company dealt with that. It was sold to us as a merger into a German company but I knew our British management wouldn't stand strong and it would end up being a takeover. Years later I would find out I was correct, all the management have moved on.

I couldn't risk the distraction and also I felt I needed to work professionally within the Digital Economy to skill myself up. The danger of developing it blind is that I start to waste time and reinvent the wheel. Something that is very common within the industry.

I also knew it was quite common for American companies to allow their employees to leave, start businesses, fund raise, scale up, before being invited back as a supplier.

I didn't bet on this approach because the British are less commercially minded but the Director did invite me back to demonstrate another product years later.

So rather than progressing with the project, I jumped ship leaving Exposé with them knowing the value of the solution would be the data centric software platform that needed to be created.

I had hoped that someone would continue Exposé in some form but that didn’t happen and they continued to develop desktop applications. I worked at a Digital Agency for two years understanding the workflow of web development. After that I secured investment to start a business and enrolled on a three month business accelerator.

The Rest is History

What would be named MultiPlug was developed in the first 10 months and while there was a temptation to return back to the 'parents' with what we had created, we decided to continue to 'eat our own dog food' by using it for our own products we eventually created.

Time and place was aligned and the Hermes Standard and the Connected Factory Exchange were born around the same time so we focused on supporting the industry to upgrade to these new standards with hardware devices we manufactured.

Today the MultiPlug can be retrofitted onto any equipment machine that hosts Windows or Linux and it runs as a background service so the possibility of 'connecting the dots' back to the original use-case is always there.

As always aligning Time & Place is key and we are now ready for the challenge to upgrade the Industry to the web browser.

A Buzzword Decade

If I had known of the buzzwords that have been coined since 2006 the concept I was pitching would have been far easier to explain.

Industry 4.0 debuted in 2016 which, while was very much misunderstood by the SMTA industry, is the alignment of Industrial Engineering with the growing Digital Economy. MultiPlug was correct in trying to unite these industries and people with the data centric internet technologies.

Fog and Edge Computing describe the difference between the Internet Cloud and what would previously be known as on-premises software, operating on what we previously called the Intranet. MultiPlug operates on the Edge, with the potential to connect to the Cloud.

More Information

About 4IR.UK British Systems

We are a Smart Factory solutions provider for the SMT Electronics Assembly manufacturing industry. We were founded in 2016 after the support of a seed funded Business Accelerator. We create hardware Adaptors that operate in more than 20 countries that extend the life of SMEMA based manufacturing equipment by providing solutions for production monitoring and supporting data connections to the Hermes Standard and the Connected Factory Exchange CFX. We also develop Software Extensions for the Low-Code No-Code MultiPlug Edge Computing Platform. The flexibility of off-the-shelf software combined with inside industrial experience means that 4IR.UK is ideally placed to anticipate and respond to a factory's changing needs.